Optical Bonding(OCA/OCR)

OCA (Optical Clear Adhesive) bonding refers to the process of using a transparent adhesive material, known as OCA, to bond a touch panel or protective glass directly onto the surface of a display, such as an LCD or OLED screen. Compared with the cost-effective DST bonding method, the full lamination by OCA bonding reduces the air gap between the touch panel or cover lens and the displays, thus minimizing reflections, improving contrast, and increasing sunlight readability.

The air gap refers to the space between the touch panel and the LCD display. Reducing or eliminating this gap helps to improve optical performance. By eliminating the air gap, optical bonding reduces internal reflections and enhances contrast, resulting in a more vibrant and clearer display. And without the light scattering and reflections, the transmittance of OCA bonding would be higher, which improves the sunlight readability of he display in bright outdoor environments. Furthermore, bonding the touch panel directly onto the LCD display increases the overall durability of the assembly by providing additional structural integrity and protection against moisture, dust, and vibrations.

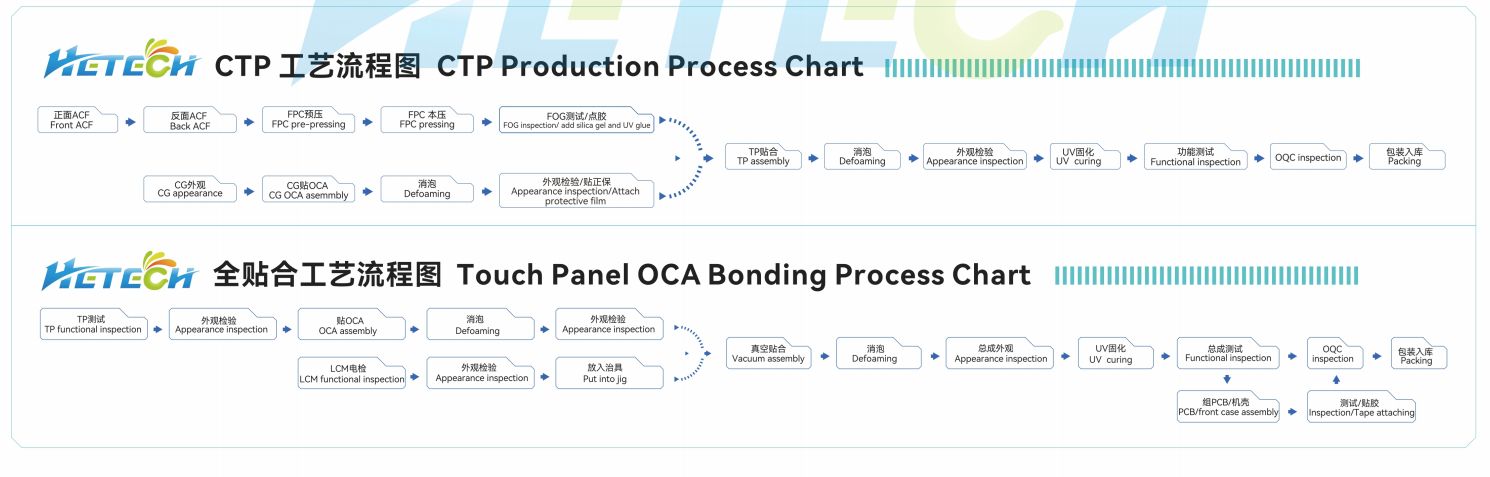

The OCA bonding process operations are maintained in ISO class 1K clean rooms, from raw material preparation, OCA alignment and bonding to CURING process. Below is the production flow chart of both capacitive touch panel and OCA bonding.

The production flow chart of OCA bonding refers to the process of solid OCA. The process would be little different if using liquid OCA. With rich experience in solid OCA bonding, Heng Cheng Electronics now could process OCA bonding for most of small&medium sized TFT LCDs. While, for some larger size industrial type displays, they are not quite compatible with solid OCA bonding due to their mechanical structure. In this situation, LOCA(liquid OCA) bonding should be considered.

The purpose of OCA bonding is to eliminate the air gap between the touch panel and the display, enhancing visual performance, increasing sunlight readability, and improving the overall durability of the display assembly. This bonding method allows for improved contrast, reduced reflections, resulting in a clearer and more vibrant display. Optical bonding is widely used in various industries, including consumer electronics, automotive, medical devices, and outdoor displays, to achieve superior display quality and robustness. Optical bonding can be customized to meet specific requirements, such as thickness, optical performance, and environmental durability.

As now OCA bonding has evolved into the mainstream. There is new bonding technology appearing, all-black-effect OCA bonding. It is a specialized technique used in the process of bonding touch panels or protective glass to displays. It’s a more advanced OCA bonding technology. The OCA it adopts is dyed OCA instead of clear optical adhesive. By applying dyed OCA, the bonded area between the touch panel and the display appears as a seamless, continuous black border. This creates an illusion of an edge-to-edge display with minimal bezels, even if there is an actual physical bezel present.

The all-black-effect OCA bonding technique is commonly used in devices that aim to achieve a sleek and modern design aesthetic with a high screen-to-body ratio. It helps to create a more immersive viewing experience by minimizing the distractions caused by visible bezels, resulting in a visually appealing and seamless display appearance.

Please contact us if you are looking for a custom display solution with OCA bonding technology for your device.

Address:Yufeng Industrial Park, Xitou Village, Minzhi Street, Longhua District, Shenzhen, Guangdong,China,518100

Copyright © Hengcheng Electronics Technolgy.(HK) Co.,Ltd ISO9001,ISO14001,ISO13485,IATF16949 approved TFT LCD manufacturer. ●●●●Your TFT LCD display solution provider!●●●●